mateusz@dprs.pl;+48 508 154 601

Transport / Petrol Tank Hose

Application: Constant volume, certified reel mounted hose suitable for deliver ing unleaded fuels (EN 228:2008) with oxygen components lim ited according to EEC 85/536 and with an aromatic content of 50% max.

Temperature range: -30°C / +90°C.

Safety factor: 4:1

Tube: NBR, black, smooth, electrically conductive.

Reinforcement: Textile braided (ID < 75mm, wrapped), 2 crossed copper wires.

Cover: CR, black, electrically conductive, abrasion resistant, oil and weather resistant, cloth impression.

Marking: Continuous ink transfer tape, yellow: “SEMPERIT S TM2 Mineralöl/Oil Tankmeister® 2 PN 20 bar R < 106 Ohm” as well as continuous embossed labelling according to EN 1761:1999 and EN12115:2011 Ω / T.

Suitable for industrial oils, diesel oils (EN 590:2010), fuel oils (DIN 51 603 parts 1 – 5), mineral oil-based hydraulic oils.

Also suitable for applications according to EN 12115 in the petro chemicals industry.

Feature: This hose has been tested according to the technical regulations for combustible liquids (TRbF) 131/2:1992.

Standard/approval: EN 1761:1999, EN 12115:2011

Notice: To ensure the assembly is leakproof, it must be tested according to EN 1761:1999 and EN 12115:2011

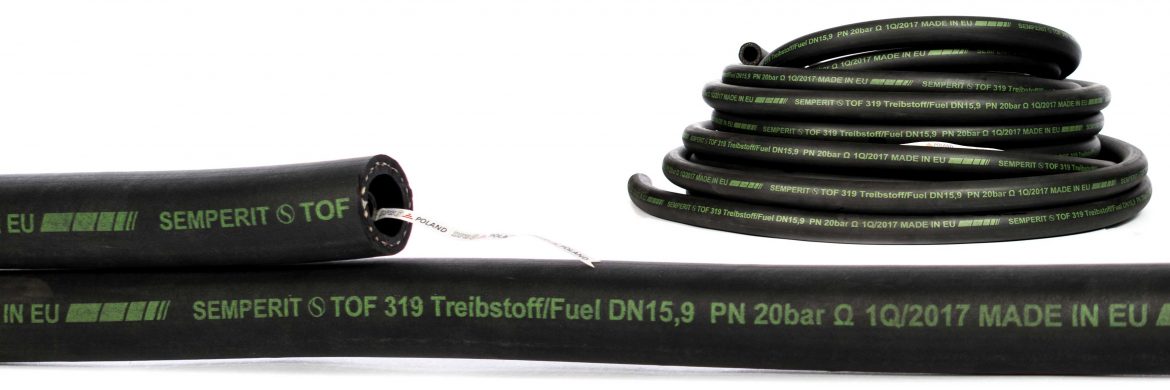

Petrol Pump Hose

Application: For the delivery of unleaded fuels (EN228:2008), diesel oils (EN 590:2010), kerosene and heating oils (DIN 51 603 parts 1 – 5).

ATTENTION: Does not conform to standard EN 1360:2005.

Temperature range: -40°C / +100°C.

Safety factor: 3:1

Tube: NBR/BR, black, smooth, electrically conductive.

Reinforcement: Textile spiral construction, 2 copper wires.

Cover: NBR/EPDM, black, smooth, electrically conductive, limited oil res istant.

Marking: Continuous coloured marking, green: “SEMPERIT S TOF 319 Treibstoff/Fuel DN PN 20 bar Ω Quarter/year”.

Petrol Pump Hose

Application: For unleaded fuels (EN 228:2008) with oxygen components lim ited according to EEC 85/536 and with an aromatic content of 50%.

Suitable for industrial oils, diesel oils (EN 590:2010), fuel oils (DIN 51 603 parts 1 – 5), and mineral-oil based hydraulic oils.

Temperature range: -30°C / +60°C.

Safety factor: 3:1

Tube: NBR, black, smooth, electrically conductive.

Reinforcement: Textile spiral construction.

Cover: CR, black, smooth, electrically conductive.

Marking: Continuous embossed labelling “SEMPERIT S TEU Treibstoff/Fuel EN 1360 Type 1 DN PN 16 bar Ω quarter/year”.

Standard/approval: EN 1360:2012.

Notice: Random lengths 5m – 60m.

Application: For conveying grout, screed, plaster and gypsum in compact flow process.

Temperature range: -35°C / +80°C.

Safety factor: 2.5 : 1

Tube: SBR/NR/BR, black, smooth, abrasion resistant, antistatic.

Reinforcement: Textile wrapped.

Cover: SBR, black, antistatic, cloth impression.

Marking: Continuous transfer tape, yellow: “SEMPERIT S SM40 Mörtel/Plaster PN 40 bar”.

Very long service life due to abrasion resistant quality of the rub ber tube and cover. The compact reinforcement package provides a very stable cross- section making the hose highly kink resistant and also offers high pressure resistance. Antistatic construction prevents the build-up of static electricity.

Notice: On request:

– with harder rubber quality and higher pressure resistance

– with steel wire braid

– with fire resistant cover

– with several cover colours.

Application:

Classic shot blast hose with excellent tube quality for conveying highly abrasive media such as quartz sand, steel shot, corundum, glass, etc.

Very long service life due to abrasion resistant tube.

Average wear of the tube 50 mm3 (according to DIN ISO 4649:2014).

Antistatic construction prevents the build-up of static electricity.

Standard/approval: Exceeds EN ISO 3861:2008.

Notice: A reinforced insert package for increased stability is available upon request.

Temperature range: -35°C / +80°C.

Safety factor: 3.5 : 1

Tube: NR/SBR/BR, black, smooth, antistatic, abrasion resistant.

Reinforcement: Textile wrapped.

Cover: SBR, black, antistatic, cloth impression.

Marking: Continuous transfer tape, red: “SEMPERIT S SM2® Sandstrahl-Shotblast PN 12 bar”.

DPRS Poland offers a highly flexible SM1 hose from SEMPERIT with extreme abrasion resistance.

Application:

Sand blasting, shot blasting, corundum, glass, sand, shots, etc.

Benefits:

Very high strength of the inner layer for abrasion

Resistance to abrasion 36mm3 acc. DIN 53516: 1987

It does not cause electrostatic shocks while maintaining work safety.

Extremely long service life due to the high abrasion resistant quality of the tube.

Average wear of the tube 36 mm3 (according to DIN ISO 4649:2014).

Antistatic construction prevents the build-up of static electricity.

Standard/approval: Exceeds EN ISO 3861:2008.

Notice: A reinforced insert package for increased stability is available upon request.

Temperature range: -35°C / +80°C.

Safety factor: 3.5 : 1

Tube: SBR/NR/BR, black, smooth, electrically conductive, highly abra sion resistant.

Reinforcement: Textile wrapped.

Cover: SBR, black, antistatic, cloth impression.

Marking: Continuous transfer tape, yellow: “SEMPERIT S SM1® Sandstrahl-Shotblast Strahlmeister® PN 12 bar”.

Brake Hose

Application: A flexible hose for hydraulic vehicle brake systems using glycine- based liquids.

Feature: Resistant to low temperatures.

Standard/approval: SAE J1401:2013. EAC (TR CU 018/2011).

Temperature range: -45°C / +70°C.

Safety factor: 7:1

Tube: SBR/BR, black, smooth.

Reinforcement: Textile braided.

Cover: EPDM, black, 2 yellow longitudinal stripes, smooth, oil and ozone resistant.

Marking: Continuous coloured marking, white: „DOT SEMPERIT 1/8 HL SAE J1401 MADE IN EU“. Opposite side continuous coloured marking, white: “Month/Year”

Fuel Hose

Application: Suitable for the delivery of unleaded fuels (EN 228:2008) and diesel oils (EN 590:2010) for cars, trucks and tractors.

Notice: Suitable for fuels with a contant of methyl-alcohol of max. 10% .

Temperature range: -40°C / +100°C, Fuel: -30°C / +70°C.

Safety factor: 3,3 : 1

Tube: NBR, black, smooth, ozone and oil resistant.

Reinforcement: Textile spiral construction.

Cover: CR/NBR, black, smooth, ozone and oil resistant.

Marking: Continuous coloured marking, green: “SEMPERIT S FUB KRAFTSTOFF/FUEL DN PN 12BAR”

Propane Butane Hose

Application: Hose for transporting propane- butane gas at low pressure in vehicles.

Temperature range: -40°C / +85°C

Safety factor: 4:1

Tube: NBR, black, smooth.

Reinforcement: Textile spiral construction.

Cover: SBR/EPDM, black, smooth.

Marking: Continuous coloured marking, white: “SEMPERIT S FPB LPG PN 4,5 bar DN quarter/year”.

SIGMA® Feed System

Application:

A suction and delivery hose for the pneumatic and hydraulic con veying of abrasive materials, such as cement, sand, phosphates, quartz, dolomite, waste glass, dry mixed animal feed, grain, bark, wood shavings, etc.

Temperature range: -35°C / +70°C.

Safety factor: 3,2 : 1

Tube: NR/BR/SBR, black, antistatic, abrasion-resistant.

Reinforcement: Textile wrapped, zinc plated steel wire helix.

Cover: CR, black, corrugated, electrically conductive, resistant to abra sion, oil, weather and sea water, cloth impression.

Marking: Continuous transfer tape, blue: “SEMPERIT S Sigma® FS 3320”.

The entire feed system is very easy to assemble due to a specially designed coupling system.

Modular construction allows for an extremely flexible hose.

External, segmented coupling system allows easy replacement of hose. Couplings can normally be reused.

Notice: The Sigma® feed system is a complete line system that contains all the necessary fittings (flanges, clamps, gaskets, reducers, elbow fittings, branches, adaptors, shut-off valves, etc.).

ATTENTION: Please refer to the Semperit resistance list or, in case of doubt, contact DPRS Poland.

ATTENTION: Please see the special handling and storage guidelines for our Sigma® system.

pl

pl en

en