mateusz@dprs.pl;+48 508 154 601

SIGMA® Feed System

Application:

A suction and delivery hose for the hydraulic transport of abrasive materials, such as gypsum, ash, bauxite, corundum, dolomite, ores, feldspar, waste glass, wood chips, industrial waste, coal, metal dust, etc.

Temperature range: -35°C / +70°C.

Safety factor: 3,2 : 1

Tube: NR, light tone, wear resistant and elastic, electrically isolating.

Reinforcement: Textile wrapped, zinc plated steel wire helix.

Cover: CR, black, corrugated, electrically conductive, resistant to abra sion, oil, weather and sea water, cloth impression.

Marking: Continuous transfer tape, red: “SEMPERIT S Sigma® FS 3310”.

Feature:

The entire feed system is very easy to assemble due to a specially designed coupling system.

Modular construction allows for an extremely flexible hose.

External, segmented coupling system allows easy replacement of hose. Couplings can normally be reused.

Notice: The SIGMA® feed system is a complete line system that contains all the necessary fittings (flanges, clamps, gaskets, reducers, elbow fittings, branches, adaptors, shut-off valves, etc.).

ATTENTION: Please refer to the Semperit resistance list or, in case of doubt, contact Semperit.

ATTENTION: Please see the special handling and storage guidelines for our SIGMA® system.

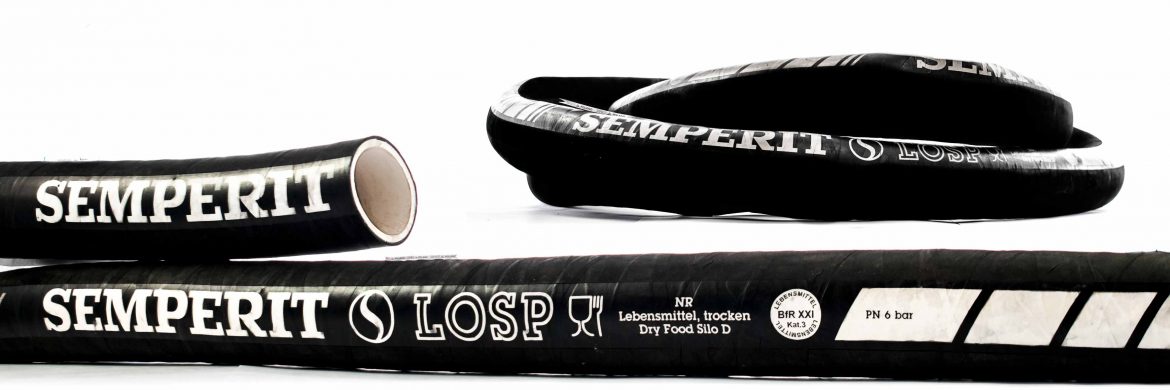

DPRS Poland offers a hose for powdery substances and powdery food SILO made by SEMPERIT.

Application:

Economical silo hose with good tube quality, for filling and dis charging silos and silo trucks.

Delivery hose for highly abrasive media such as cement, sand, gravel, granulated materials, pellets, etc.

Long service life due to abrasion resistant tube. Especially flexible and therefore easy to handle. Antistatic hose construction and inter-woven copper wire to pre vent the build-up of static electricity.

Temperature range: -35°C / +80°C.

Safety factor: 3.15 : 1

Tube: NR/SBR/BR, black, smooth, antistatic.

Reinforcement: Textile wrapped, copper wire.

Cover: SBR, black, cloth impression.

Marking: Continuous transfer tape, silver: „SEMPERIT S SILO Silo D PN 6bar“

Silo Hose

Application:

Premium silo hose with excellent tube quality, for filling and dis charging silos and silo trucks.

Delivery hose for highly abrasive media such as cement, sand, gravel, granulated materials, pellets, etc.

Very long service life due to abrasion resistant tube Especially flexible and therefore easy to handle. Antistatic hose construction and inter-woven copper wire to pre vent the build-up of static electricity.

Standard/approval: Exceeds EN ISO 3861:2008.

Temperature range: -35°C / +80°C.

Safety factor: 3.15 : 1

Tube: SBR/NR/BR, black, smooth, highly abrasion resistant, antistatic.

Reinforcement: Textile wrapped, copper wire.

Cover: SBR, black, antistatic, cloth impression.

Marking: Continuous transfer tape, silver: “SEMPERIT S SOSH Hochantiabrasiv Silo D PN 6bar”

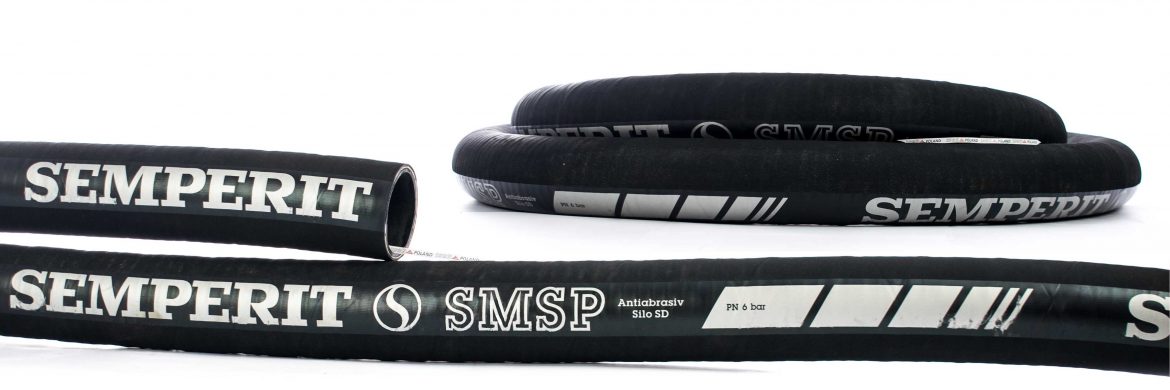

Silo Hose

Application:

Silo hose with very good tube quality for filling and discharging silos and silo trucks.

Suction and delivery hose for highly abrasive media such as cement, sand, gravel, granulated materials, pellets, etc.

Temperature range: -35°C / +80°C.

Safety factor: 3.15 : 1

Tube: NR/SBR/BR, black, smooth, antistatic, abrasion resistant.

Reinforcement: Textile wrapped, helix, copper wire.

Cover: SBR, black, antistatic, cloth impression.

Marking: Continuous transfer tape, silver: “SEMPERIT S SMSP antiabrasiv Silo SD PN 6 bar”.

The built-in wire helix, improves cross-sectional stability, allows smaller bending radii and makes the hose suitable for suction purposes.

Very long service life due to abrasion resistant tube. Especially flexible and therefore easy to handle.

Antistatic hose construction and inter-woven copper wire pre vents the build-up of static electricity.

Notice: Various hose ends available on request.

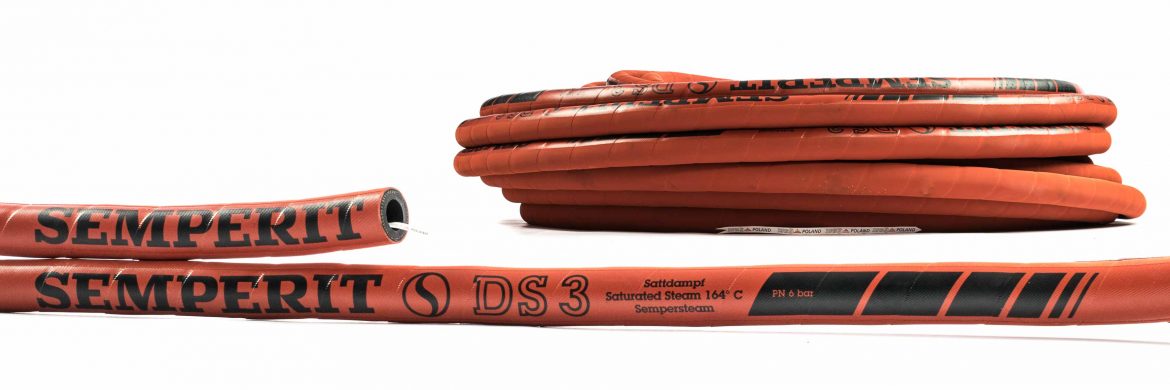

DPRS Poland offers a flexible hose type DS1 made by SEMPERIT for steam and hot water. Used for professional industrial equipment.

ATTENTION: Superheated steam shortens considerably the ser vice life of the hose!

ATTENTION: Please refer to the saturated steam table. Temperature range: +164°C (saturated steam), +95°C (hot water).

Safety factor: Steam 10: 1, Water 3.15 : 1

Tube: SBR/EPDM, black, smooth, antistatic.

Reinforcement: Textile wrapped.

Cover: SBR/NBR, red, limited grease and oil resistance, cloth impression.

Marking: Continuous transfer tape, black: “SEMPERIT S DS3 Sattdampf/Saturated Steam 164°C Semper steam PN 6 bar“.

DPRS Poland offers a flexible hose type DS1 made by SEMPERIT for steam and hot water. Used for professional industrial equipment.

Application: Suitable for conveying saturated steam and hot water.

Feature: Electrically conductive: Resistance R<106 Ohm. Tried and tested by the chemical industry.

Standard/approval: EN ISO 6134:2005 Type 2, class A; (supersedes DIN 2825:1994).

Temperature range: +210°C (saturated steam), +120°C (hot water).

Safety factor: Steam 10: 1, Water 3.15 : 1

Tube: EPDM, black, smooth, electrically conductive.

Reinforcement: Steel wire braided, zinc-plated.

Cover: EPDM, black, electrically conductive, cloth impression.

Marking: Continuous transfer tape, red: “SEMPERIT S DS1 Sattdampf/ Saturated Steam 210°C Semper steam PN 18 bar R < 106 Ohm” as well as red embossed labelling according to EN ISO 6134 (with EN dimensions).

Hose conforms to DIN 2825:1994, which has been superseded by EN ISO 6134:2005.

ATTENTION: Use only suitable fittings (clamp fittings according to EN 14423:2005).

ATTENTION: Superheated steam shortens considerably the service life of the hose!

ATTENTION: Please refer to our saturated steam table.

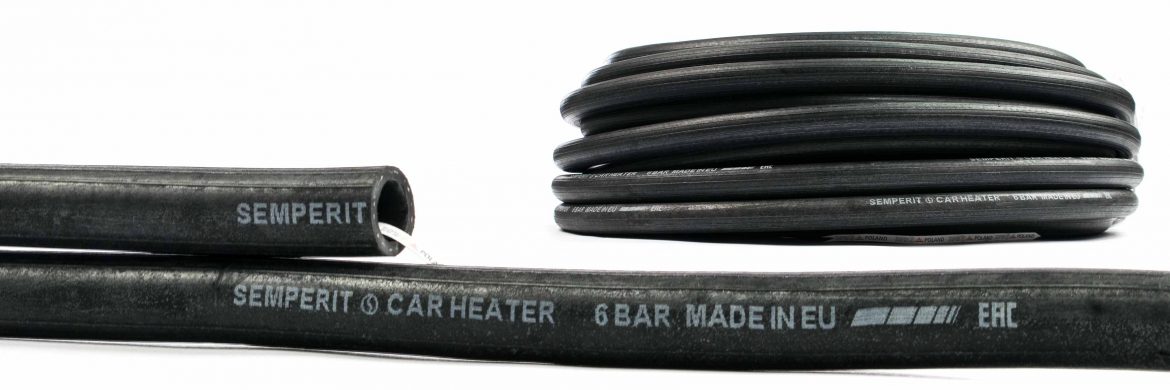

DPRS Poland offers a highly flexible hose for cold and hot water type FKE made by SEMPERIT. The hose is mainly used in industry, manufacturing plants and motorization.

High-quality flexible hose for the transmission of cooling water and glycol-based mixtures. Made according to the EAC standard (TR CU 018/2011). The FKE hose is resistant to weather conditions (ozone and UV radiation) and high temperatures, and also maintains flexibility at low temperatures.

The inner layer is made of black, smooth EPDM rubber, which is characterized by high resistance to deformation under the influence of mechanical forces.

Temperature range: -25°C / +100°C.

Safety factor: 2 : 1

Tube: EPDM, black, smooth.

Reinforcement: Textile spiral construction.

Cover: EPDM, black, grooved.

Marking: Continuous coloured marking, white: „SEMPERIT S CAR HEATER 6 BAR MADE IN EU ////// EAC”.

DPRS Poland offers a flexible FLEXICH UPEL hose made by well-known SEMPERIT for transferring chemicals used mainly in industry.

Extremely flexible hose, specially designed to work with chemicals. Made according to the standards EN 12115: 2011, TRbF 131/2: 1992. The variant of the black UPE foil ensures the conductivity of electric charges.

Application:

Suitable for the transport of acids, alkaline substances, salts, organic compounds (alcohols, esters, ketones), including aromatic substances, chlorinated hydrocarbons and oxidizing acids.

Flexichem, the highly flexible chemical protection hose with a black, conductive UPE liner.

Suitable for the transport of acids, alkalis, salts, organic com pounds (alcohols, esters, ketones, etc.) incl. aromatic substances, chlorinated hydrocarbons and oxidising acids (cf. our chemical resistance list).

Feature: The UPE tube has an extremely low friction coefficient and good abrasion resistance.

Standard/approval: EN 12115:2011, TRbF 131/2:1992.

ATTENTION: The temperature of the medium must be lower than its boiling point.

ATTENTION: Please refer to the Semperit resistance list or, in case of doubt, contact DPRS Poland.

ATTENTION: Continuous use at the peak values reduces the ser vice life.

ATTENTION: To ensure the assembly is leakproof, it must be tested according to EN 12115:2011.

Temperature range: Tube, depending on the discharge medium up to +100°C, hose, flexible down to -35°C. Steam cleaning, without pressure, up to 130°C / max. 30 min.

Safety factor: 4 : 1

Tube: UPE, black, smooth, electrically conductive.

Reinforcement: Special rubber foil, textile wrapped, 2 crossed copper wires, zinc plated steel wire helix.

Cover: EPDM, black, smooth, electrically conductive, abrasion resistant, weather resistant, cloth impression.

Marking: Continuous transfer tape, blue/white: “SEMPERIT S FLEXICHEM CHEMIE UPEL”, and continuous embossed labelling: “SEMPERIT S EN 12115 FLEXICHEM SD (DN). PN .. bar Ω / T quarter/year TRbF 131/2”.

DPRS Poland offers a flexible suction and delivery hose LM4S made by SEMPERIT used in bottling plants, dairies, slaughterhouses, vegetable processing plants, fruit processing plants, at the unloading and loading of dairy tanks and many others.

Application:

Flexible suction and delivery food hose intended for the transmission of products containing animal and vegetable fats and cooking oils

Also suitable for beverages and for milk and dairy products

Standards: BgW XXI: 2002 (Cat. 2), TDT

Note: Very good resistance to many aggressive cleaning and disinfecting agents. For details, please look at the separate information.

Temperature range: -35°C / +95°C steam cleaning up to max. 130°C / 30 min, unpres surised.

Safety factor: 3.15 : 1

Tube: NBR, white, smooth, food quality, grease and oil resistant.

Reinforcement: Textile wrapped , zinc plated steel wire helix.

Cover: NVC, blue, resistant to abrasion and ageing, cloth impression.

Marking: Continuous transfer tape, white: “SEMPERIT S LM4S/SF 1500 – NBR Lebensmittel/Fatty Goods SD PN 10 bar”. Suitable for use in the food and drinks industry for conveying milk and dairy products.

Standard/approval: BfR (former BgVV) XXI:2002 (Kat. 2), FDA (CFR 21 § 177.2600).

Notice: Smooth tube allows for easy cleaning. For the application of cleaning agents, please refer to our separate information sheet.

ATTENTION: Not suitable for dry conveyance. On request with plastic helix.

DPRS Poland offers a high quality hose for food substances LM3 made by SEMPERIT, used mainly in transport to tanks with food liquids and the carbonated beverages, alcoholic beverages and dairy products. The LM3 Semperit hose, due to its high temperature resistance, is also used to keep food plants clean using steam or water.

Application:

Flexible food hose used for steam and hot water cleaning in food processing plants

Also suitable for the transmission of products containing condensed animal and vegetable fats, cooking oils, milk and milk products

Standards: BgW XXI: 2002 (Cat.2), PZH, TDT.

Attention:

We recommend DS1, DS2 / E and DS3 hoses for the transmission of steam in industrial end-uses

Very good resistance to many aggressive cleaning and disinfection agents.

Temperature range: -35 ° C / +95 ° C hot water / + 164 ° C steam.

Standard/approval: BfR (former BgVV) XXI:2002 (Kat.2), FDA (CFR 21 § 177.2600).

Notice:

To meet the high demands associated with continuous steam operation we recommend DS1, DSE or DS3 hoses.

Very high resistance to many aggressive cleaning agents.

For the application of cleaning agents, please refer to our separ ate information sheet.

Temperature range: -35°C / +95°C hot water / +164°C saturated steam.

Safety factor: Steam: 10 : 1, hot water: 3.15 : 1

Tube: NBR, white, smooth, food quality, grease and oil resistant.

Reinforcement: Textile wrapped.

Cover: NVC, blue, grease and oil resistant, cloth impression.

Marking: Continuous transfer tape, white: “SEMPERIT S LM3 – NBR Lebensmittel/Dampf/Food/Steam D PN 6 bar 164°C Dampf”.

pl

pl en

en