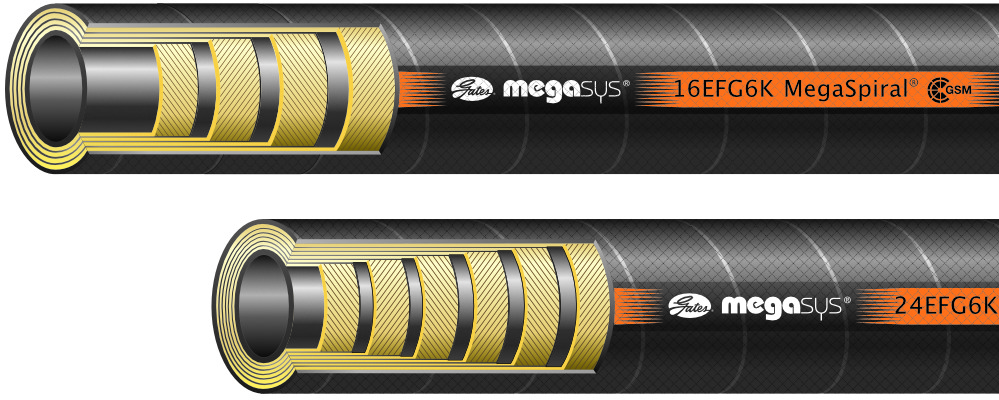

MEGASYS® EFG6K hydraulic hose 420 bar GATES

Recommended for extremely high pressure and high impulse applications such as hydrostatic transmissions. EFG6K is designed to meet or exceed all requirements of SAE 100R15 specifications and performance requirements of EN 856 4SP (-6, -8, -10 and -12), EN 856 4SH (-12, -16, and -20), and ISO 3862 Type R15 (-6, -8, -10, -12, -16, -24). 12EFG6K meets ISO 18752 Grade D. Recommended Couplings: GlobalSpiral™ Couplings, GlobalSpiral™ MAX Pressure Couplings, Stainless Steel S Couplings (-6 through -20).

- EFG6K hose is compatible with biodegradable hydraulic fluids like synthetic esters, polyglycols and vegetable oils as well as petroleum-based fluids.

- Superior flex impulse performance: Tested to 1,000,000 impulse cycles at 50% of SAE 100R15 bend radii (except -32).

FEATURES AND BENEFITS

- -6 to -20 validated with GlobalSpiral™; -24, -32 with GlobalSpiral™ Maximum.

- Up to 40% of EN 856 4SP/4SH bend radius at rated working pressure.

- EFG6K MegaSpiral™ is rated at 1/2 bend radius of SAE 100R15.

- Meets Flame Resistance Acceptance Designation MSHA 2G.

- Type approvals: DNV, GL, LR, BV and ABS.

- 6000 PSI constant pressure for all ID’s.

- Cover: MSHA approved

RECOMMENDED; Extremely high pressure and high impulse hydraulic applications.

TUBE: NBR (Nitrile) based.

REINFORCEMENT: Four (six for -20 to -32) alternating layers of spiralled, high tensile steel wire.

COVER: CR (Chloroprene) based. MSHA approved.

TEMPERATURE RANGE: -40°c to +121°c.

NORMS:EN 856 4SP/4SH, ISO 3862 R15, SAE 100R15

MEGASYS® M6K hydraulic hose 420 bar GATES

Recommended for high-pressure hydraulic applications. Easy to route and to install in extremely tight areas. Exceeds ISO 18752 Grade B. Recommended Couplings: GlobalSpiral™ Couplings, MegaCrimp® Couplings, Stainless Steel B Couplings.

- M6K hose is compatible with biodegradable hydraulic fluids like synthetic esters, polyglycols and vegetable oils as well as petroleum-based fluids.

- Superior flex impulse performance: Tested to 600,000 impulse cycles, 3 times the industry standard.

- Meets Flame Resistance Acceptance Designation MSHA 2G.

FEATURES AND BENEFITS

- Provides tighter than standard minimum bend radius and greater flexibility for easier plumbing.

- 70% of EN 857 2SC and 50% of EN 853 2SN bend radius at rated working pressure.

- Type approvals: DNV, GL, LR and BV.

- Validated with MegaCrimp®.

- Working pressure: 42 MPa.

- Cover: MSHA approved.

RECOMMENDED: for high pressure hydraulic applications, easy to route and to install in tight areas.

TUBE: NBR (Nitrile) based.

REINFORCEMENT: two braids of high tensile steel wire.

COVER: NBR/PVC (Nitrile and PVC) based, MSHA approved.

TEMPERATURE RANGE: -40°c to +100°c constant and +121°c intermittent.

NORMS: ISO 18752

Source: Gates

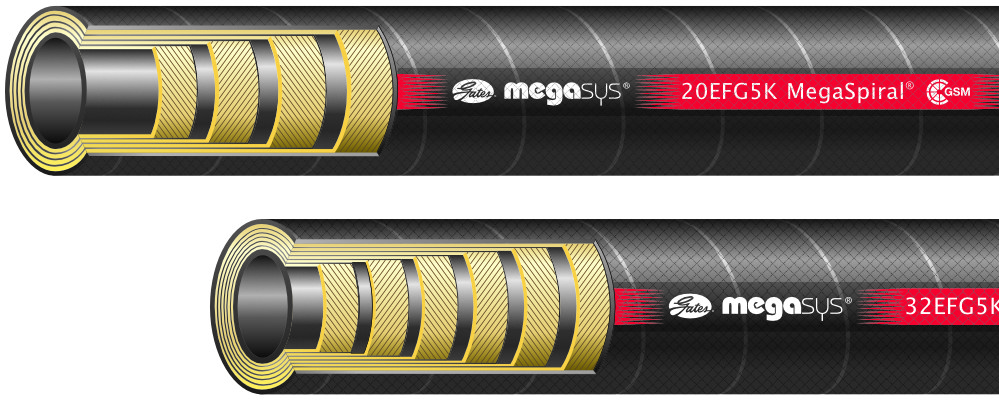

MEGASYS® EFG5K hydraulic hose 350 bar GATES

Recommended for extremely high pressure and high impulse hydraulic applications. EFG5K is designed to meet or exceed all requirements of ISO 3862 R13 specifications and performance requirements of EN 856 4SP (-10 to -32) and EN 856 4SH (-20 to -32). Recommended Couplings: -6 to -20: GlobalSpiral™; -24, -32: GlobalSpiral™ Maximum.

- EFG5K hose is compatible with biodegradable hydraulic fluids like synthetic esters, polyglycols and vegetable oils as well as petroleum-based fluids.

- Superior flex impulse performance: Tested to 1,000,000 impulse cycles at 50% of EN 856 R13 and SAE 100R13 bend radii (except -32).

FEATURES AND BENEFITS

- Up to 40% of EN 856 4SP/4SH bend radius at rated working pressure.

- EFG5K MegaSpiral™ is rated at 1/2 bend radius of SAE 100R13.

- Meets Flame Resistance Acceptance Designation MSHA 2G.

- Type approvals: DNV, GL, LR, BV and ABS.

- 5000 PSI constant pressure for all ID’s.

- Cover: MSHA approved.

RECOMMENDED; Extremely high pressure and high impulse hydraulic applications.

TUBE: NBR (Nitrile) based.

REINFORCEMENT: Four (six for -20 to -32) alternating layers of spiralled, high tensile steel wire.

COVER: CR (Chloroprene) based. MSHA approved.

TEMPERATURE RANGE: -40°c to +121°c.

NORMS: EN 856 4SP/4SH, EN 856 R13, ISO 18752, ISO 3862 R13, SAE 100R13.

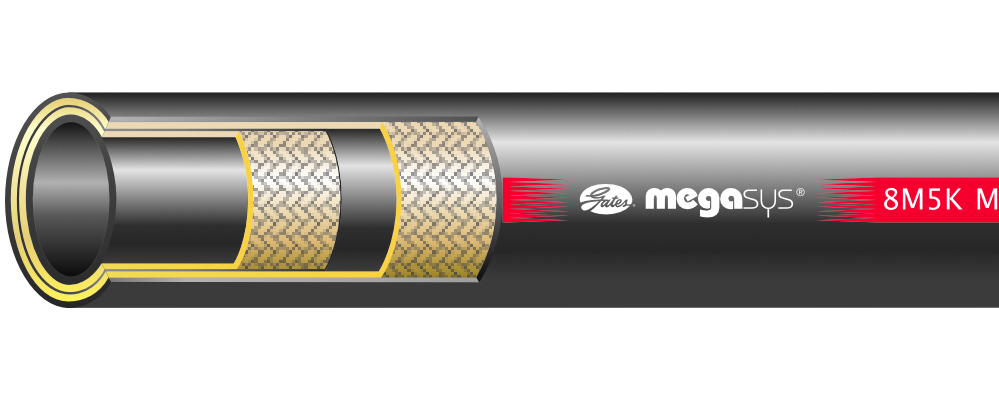

MEGASYS® M5K hydraulic hose 350 bar GATES

Recommended for high-pressure hydraulic applications. Easy to route and to install in extremely tight areas. Meets or exceeds requirements of EN 857 2SC and ISO 18752 Grade B.

- M5K hose is compatible with biodegradable hydraulic fluids like synthetic esters, polyglycols and vegetable oils as well as petroleum-based fluids.

- Superior flex impulse performance: Tested to 600,000 impulse cycles, 3 times the industry standard.

- Meets Flame Resistance Acceptance Designation MSHA 2G.

FEATURES AND BENEFITS

- Provides tighter than standard minimum bend radius and greater flexibility for easier plumbing.

- 70% of EN 857 2SC and 50% of EN 853 2SN bend radius at rated working pressure.

- Type approvals: DNV, GL, LR and BV.

- Standards: Gates proprietary.

- Validated with MegaCrimp®.

- Working pressure: 35 MPa.

- Cover: MSHA approved.

RECOMMENDED: for high pressure hydraulic applications, easy to route and to install in tight areas.

TUBE: NBR (Nitrile) based.

REINFORCEMENT: two braids of high tensile steel wire.

COVER: NBR/PVC (Nitrile and PVC) based, MSHA approved.

TEMPERATURE RANGE: -40°c to +100°c constant and +121°c intermittent.

NORMS: ISO 18752

Source: Gates

MEGASYS® EFG4K hydraulic hose 280 bar GATES

Recommended for extremely high pressure and high impulse hydraulic applications. EFG4K exceeds requirements for ISO 18752 Grade D, SAE 100R12, EN 856 R12 and ISO 3862 Type R12. Recommended Couplings: GlobalSpiral™ Couplings (-6 through -20) Special One-Piece 20MGS Coupling (MC4-20 Crimper Only) (-20), Stainless Steel S Couplings.

- EFG4K hose is compatible with biodegradable hydraulic fluids like synthetic esters, polyglycols and vegetable oils as well as petroleum-based fluids.

- Superior flex impulse performance: Tested to 1,000,000 impulse cycles at 50% of EN 856 R12 and SAE 100R12 bend radii.

FEATURES AND BENEFITS

- Meets or exceeds performance requirements of EN 856 4SP (-16, -20).

- Meets Flame Resistance Acceptance Designation MSHA 2G.

- EFG4K MegaSpiral™ is rated at 1/2 bend radius of SAE 100R12.

- Most flexible EN 856 R12 / SAE 100R12 hose in the industry.

- 40% of EN 856 4SP bend radius at rated working pressure.

- Type approvals: DNV, GL, LR, BV and ABS.

- 4000 PSI constant pressure for all ID’s.

- Validated with GlobalSpiral™.

- Cover: MSHA approved.

RECOMMENDED; For very high–pressure, high–impulse applications.

TUBE: NBR (Nitrile) based.

REINFORCEMENT: Four alternating layers of spiraled, high-tensile steel wire.

COVER: CR based (Polychloroprene), MSHA approved.

TEMPERATURE RANGE: -40°c to +121°c.

NORMS: EN 856 R12, ISO 18752, ISO 3862 R12, SAE 100R12

Source: Gates

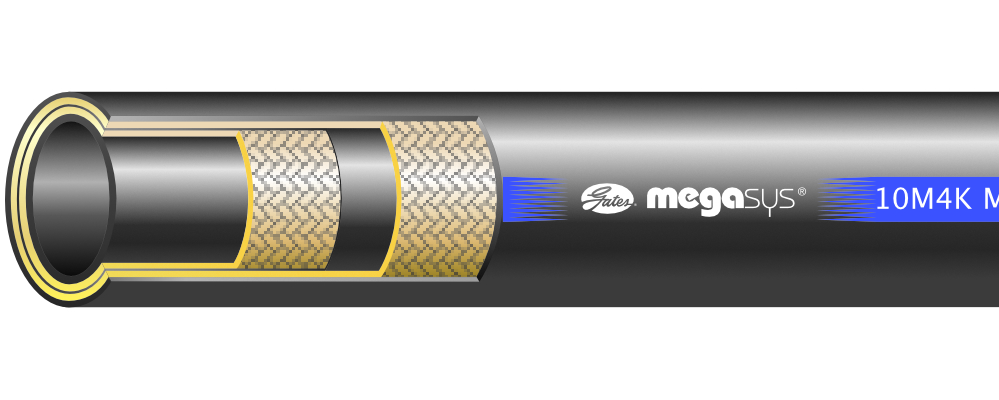

MEGASYS® M4K hydraulic hose 280 bar GATES

Recommended for high-pressure hydraulic oil line applications. Easy to route and to install in extremely tight areas. Meets or exceeds requirements of ISO 18752 Grade B, SAE 100R19, EN 857 2SC and ISO11237 R19.

- M4K hose is compatible with biodegradable hydraulic fluids like synthetic esters, polyglycols and vegetable oils as well as petroleum-based fluids.

- Superior flex impulse performance: Tested to 600,000 impulse cycles, 3 times the industry standard.

- Meets Flame Resistance Acceptance Designation MSHA 2G.

FEATURES AND BENEFITS

- Provides greater performance, flexibility, easier routing and plumbing of mobile and stationary hydraulic platforms.

- 50% of EN 857 2SC and 40% of EN 853 2SN bend radius at rated working pressure.

- Alternative to spiral hoses in high pressure lines where flexibility is required.

- Type approvals: DNV, GL, LR, BV and ABS.

- Validated with MegaCrimp®.

- Working pressure: 28 MPa.

- Cover: MSHA approved.

RECOMMENDED: for high pressure hydraulic applications, easy to route and to install in tight areas.

TUBE: NBR (Nitrile) based.

REINFORCEMENT: two braids of high tensile steel wire.

COVER: Black, oil, abrasion and weather resistant, synthetic rubber (Nitrile and PVC), MSHA approved.

TEMPERATURE RANGE: -40°c to +100°c constant and +121°c intermittent.

NORMS: meets or exceeds ISO 11237 R19 SAE 100R19 performance requirements.

Source: Gates

MEGASYS® EFG3K hydraulic hose 210 bar GATES

Recommended for extremely high pressure and high impulse hydraulic applications. Exceeds all performance requirements for ISO 18752 Grade D, SAE 100R12, EN 856 R12, performance requirements of EN 856 4SP, and ISO 3862 Type R12.

- EFG3K hose is compatible with biodegradable hydraulic fluids like synthetic esters, polyglycols and vegetable oils as well as petroleum-based fluids.

- Superior flex impulse performance: Tested to 1,000,000 impulse cycles at 50% of EN 856 R12 and SAE 100R12 bend radii (except -32).

FEATURES AND BENEFITS

- EFG3K is rated at 1/2 the SAE 100R12 minimum bend radius and is 3000 working pressure in all ID’s.

- -20 validated with GlobalSpiral™; -24 to -32 with GlobalSpiral™ Plus.

- Up to 40% of EN 856 4SP bend radius at rated working pressure.

- Meets Flame Resistance Acceptance Designation MSHA 2G.

- Type approvals: DNV, GL, LR, BV and ABS.

- Cover: MSHA approved.

RECOMMENDED; Very high–pressure, high–impulse applications.

TUBE: NBR (Nitrile) based.

REINFORCEMENT: Four alternating layers of spiraled, high-tensile steel wire.

COVER:Black, oil resistant, synthetic rubber (Polychloroprene), MSHA approved.

TEMPERATURE RANGE: -40°c to +121°c.

Source: Gates

MEGASYS® M3K hydraulic hose 225 bar GATES

Recommended for high-pressure hydraulic oil line applications. Easy to route and to install in extremely tight areas. Exceeds ISO 18752 Grade B, SAE 100R17 and ISO11237 R17 working pressure, minimum bend radius requirements and performance requirements of EN 857 1SC.

- M3K hose is compatible with biodegradable hydraulic fluids like synthetic esters, polyglycols and vegetable oils as well as petroleum-based fluids.

- Superior flex impulse performance: Tested to 600,000 impulse cycles, 3 times the industry standard.

- Meets Flame Resistance Acceptance Designation MSHA 2G.

BENEFITS

- 70% of EN 857 1SC/2SC and 50% of EN 853 1SN/2SN bend radius at rated working pressure.

- Mega3000 rated at 3250 PSI working pressure and 13,000 burst for all ID’s.

- Exceeds working pressure requirements of R17.

- Type approvals: DNV, GL, LR, BV and ABS.

- Validated with MegaCrimp®.

- Cover: MSHA approved.

RECOMMENDED: for high pressure hydraulic applications, easy to route and to install in tight areas.

TUBE: NBR (nitrile) based.

REINFORCEMENT: -4 to -8: one braid of high tensile steel wire; -10 to -16: two braids of high tensile steel wire.

COVER: NBR/PVC based, MSHA approved.

TEMPERATURE RANGE: -40°c to +100°c constant and +121°c intermittent.

NORMS: EN 857 1SC, ISO 11237 R17, ISO 18752, SAE 100R17.

Source: Gates

pl

pl en

en