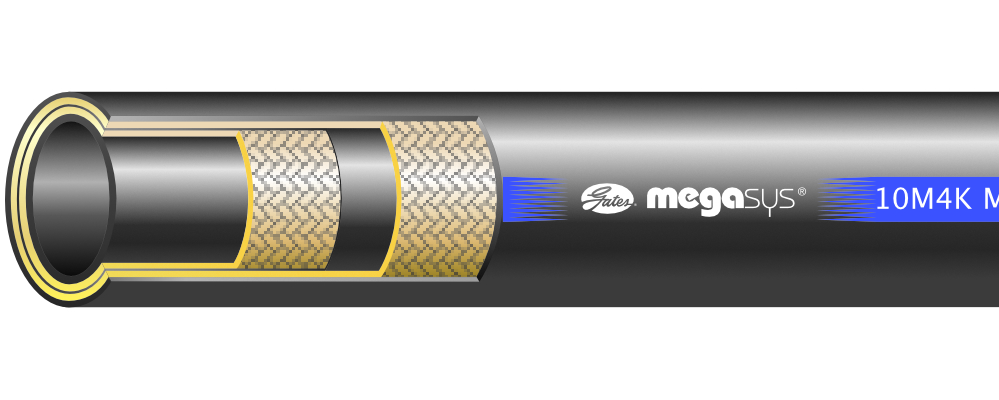

MEGASYS® M4K hydraulic hose 280 bar GATES

Recommended for high-pressure hydraulic oil line applications. Easy to route and to install in extremely tight areas. Meets or exceeds requirements of ISO 18752 Grade B, SAE 100R19, EN 857 2SC and ISO11237 R19.

- M4K hose is compatible with biodegradable hydraulic fluids like synthetic esters, polyglycols and vegetable oils as well as petroleum-based fluids.

- Superior flex impulse performance: Tested to 600,000 impulse cycles, 3 times the industry standard.

- Meets Flame Resistance Acceptance Designation MSHA 2G.

FEATURES AND BENEFITS

- Provides greater performance, flexibility, easier routing and plumbing of mobile and stationary hydraulic platforms.

- 50% of EN 857 2SC and 40% of EN 853 2SN bend radius at rated working pressure.

- Alternative to spiral hoses in high pressure lines where flexibility is required.

- Type approvals: DNV, GL, LR, BV and ABS.

- Validated with MegaCrimp®.

- Working pressure: 28 MPa.

- Cover: MSHA approved.

RECOMMENDED: for high pressure hydraulic applications, easy to route and to install in tight areas.

TUBE: NBR (Nitrile) based.

REINFORCEMENT: two braids of high tensile steel wire.

COVER: Black, oil, abrasion and weather resistant, synthetic rubber (Nitrile and PVC), MSHA approved.

TEMPERATURE RANGE: -40°c to +100°c constant and +121°c intermittent.

NORMS: meets or exceeds ISO 11237 R19 SAE 100R19 performance requirements.

Source: Gates

MEGASYS® EFG3K hydraulic hose 210 bar GATES

Recommended for extremely high pressure and high impulse hydraulic applications. Exceeds all performance requirements for ISO 18752 Grade D, SAE 100R12, EN 856 R12, performance requirements of EN 856 4SP, and ISO 3862 Type R12.

- EFG3K hose is compatible with biodegradable hydraulic fluids like synthetic esters, polyglycols and vegetable oils as well as petroleum-based fluids.

- Superior flex impulse performance: Tested to 1,000,000 impulse cycles at 50% of EN 856 R12 and SAE 100R12 bend radii (except -32).

FEATURES AND BENEFITS

- EFG3K is rated at 1/2 the SAE 100R12 minimum bend radius and is 3000 working pressure in all ID’s.

- -20 validated with GlobalSpiral™; -24 to -32 with GlobalSpiral™ Plus.

- Up to 40% of EN 856 4SP bend radius at rated working pressure.

- Meets Flame Resistance Acceptance Designation MSHA 2G.

- Type approvals: DNV, GL, LR, BV and ABS.

- Cover: MSHA approved.

RECOMMENDED; Very high–pressure, high–impulse applications.

TUBE: NBR (Nitrile) based.

REINFORCEMENT: Four alternating layers of spiraled, high-tensile steel wire.

COVER:Black, oil resistant, synthetic rubber (Polychloroprene), MSHA approved.

TEMPERATURE RANGE: -40°c to +121°c.

Source: Gates

UNIVERSAL PRODUCT CODEHydraulic hose MXT GATES

MEET MXT. THE NEXT GENERATION OF

PREMIUM HYDRAULICS.

MXT™ is an innovative addition to Gates premium, MegaSys™ Hydraulics portfolio that leverages our materials science and process technologies to deliver a lighter weight, flexible and more compact solution without compromising performance.

Over the last 50 years, Gates has driven standard adoption in the industry. We have used our extensive knowledge of standards, industries and applications, as well as our expertise in materials science to create a competitive edge for our customers by developing cross-functional hydraulic solutions that offer premium performance.

RECOMMENDED: for high pressure hydraulic applications, easy to route and to install in tight areas.

TUBE: synthetic rubber.

REINFORCEMENT: braid of high tensile steel wire.

COVER: synthetic rubber (Nitrile and PVC), MSHA approved.

TEMPERATURE RANGE: -40°c to +100°c

NORMS: EN 853 2SN i EN 857 2SC, EN 853 2SN i EN 857 2SC, SAE 100R16, SAE 100R2, SAE 100R17 (-6, -8, -10, and -12), SAE 100R19 (-6 and -8)

Source: Gates

pl

pl en

en